Case Studies

A BREATH OF FRESH AIR FOR A MINNESOTA SCHOOL DISTRICT White Paper | QLCI Displacement Chilled Beams

Background

In 2002, the American National Standards Institute (ANSI) published ANSI S12.60, Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools. In essence, this standard calls for a 35 dBA (approximately NC27) acoustical level in all core learning areas.

The Anoka-Hennepin School District is the largest school district in Minnesota; it comprises most of the suburbs on the north side of Minneapolis. In 2004, the district allocated monies for the retrofit of existing elementary and middle schools based on IAQ improvement within the classroom. Interestingly, the addition of air conditioning for the schools did not qualify for the monies although the implementation of the space humidity control was allowed under the allocation. The Planning and Management Team for the school district was particularly attracted to the QLCI displacement with induction terminals as a solution for the planned classroom retrofits as well as continuing new school designs.

As the air conditioning of the classrooms did not qualify for the allocated funds, the heat transfer coils within the QLCI terminals were configured for heating only at this time. However, they were piped such that the inclusion of a chilled water circuit could be easily accomplished in the future. While there was no cooling contribution from the coil, the delivery of 55°F air from the air handling unit (required to accomplish de-humidification of the space) achieved a minimal level of classroom cooling.

QLCI Key Benefits:

- Improved removal of heat-associated contaminants inherent to thermal displacement ventilation systems.

- Classroom acoustical levels compliant with ANSI S12.60

- Designed for direct integration with a DOAS system to allow delivery of primary air at the space minimum ventilation rate.

- Lower maintenance requirements than other available classroom HVAC terminals.

In May 2005, the district installed a mock-up of the QLCI system in a classroom in an elementary school where the first retrofit was to be performed. Among the performance parameters studied were the acoustics and the CO2 concentration within the classroom. These were compared to those of an adjacent classroom served by a mixed air system (unit ventilators) under similar thermal loads and occupancy.

Classroom Acoustical Studies

Subsequent to the issuance of this standard the Air Conditioning and Refrigeration Institute (ARI) commissioned ATS&R (a Minnesota-based A/E firm that specializes in educational facility design and renovation) and Kvernstoen, Ronnholm & Associates (a Minneapolis area acoustical

consultant) to perform a study of acoustical levels in area schools.

The primary objectives of the study were:

- Provide a survey of classroom acoustics in existing installations.

- Identify potential design solutions and estimated cost of achieving compliance in classrooms that did not meet the requirements of Standard S12.60.

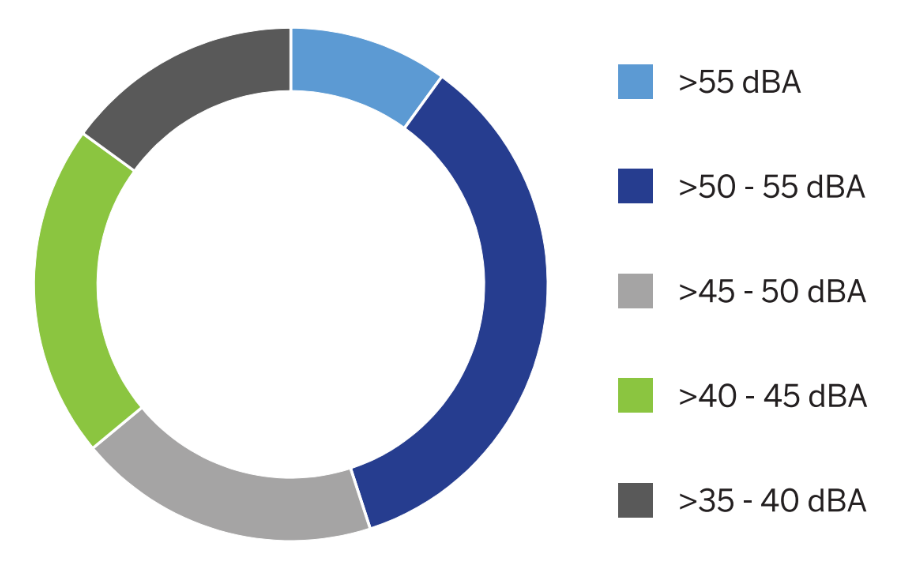

Sixteen schools (primarily located in Minnesota) and 48 classrooms were evaluated in the study, the results of which were published in October 2005. Ambient noise levels in the classrooms ranged from 36 to 58 dBA, resulting in only one (1) classroom complying with ANSI S12.60 requirements. The average classroom noise level was 47 dBA (approximately NC40). Figure 1 illustrates the summary of these acoustical tests.

ATS&R was contracted as the A/E consultant for the planned retrofit of the Anoka-Hennepin Schools. In June 2005, Kvernstoen, Ronnholm & Associates was commissioned to measure the combined acoustical performance of the three (3) QLCI displacement terminals installed in the mock-up at a combined primary air ow rate of 450 CFM (the minimum ventilation ow rate for the classroom). These tests were conducted during the late evening (approximately 10 PM) to minimize the effect of background noise. The results confirmed that the QLCI system produced noise levels compliant with Standard S12.60. A similar test of the unit ventilator in the adjacent classroom resulted in a noise level of 55 dBA.

Classroom Contaminant Concentrations

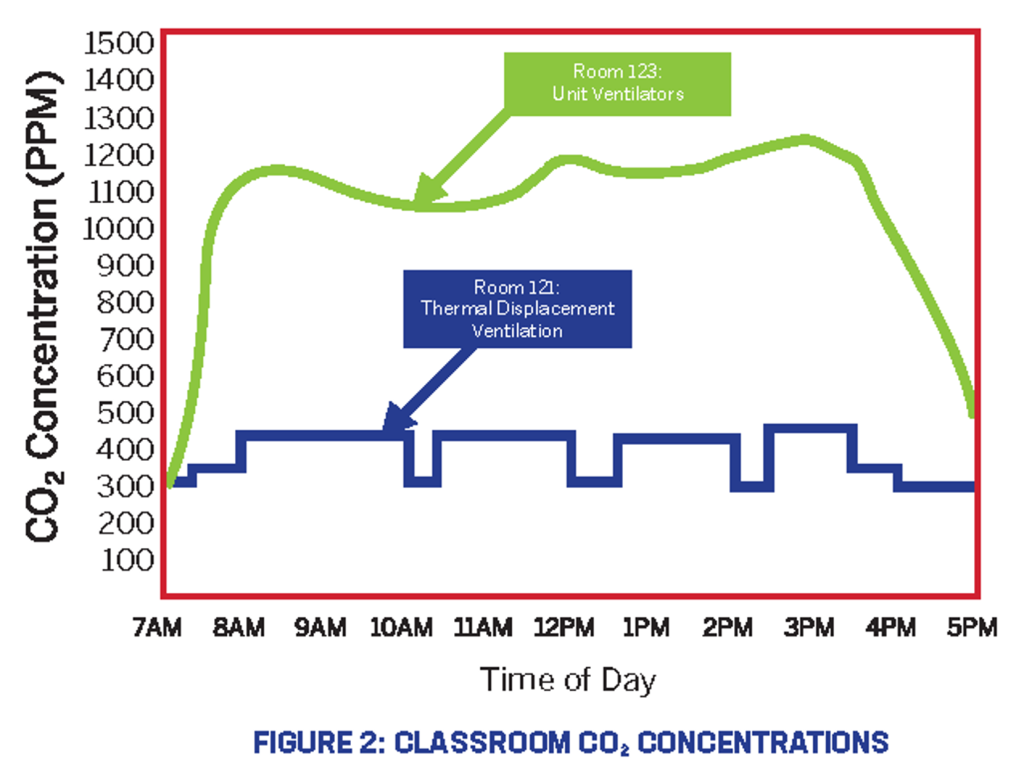

In an effort to substantiate the contaminant removal efficiency superiority of the QLCI displacement terminals (versus the unit ventilator), a CO2 sensor was hung at the center (6-foot height) of each of the aforementioned classrooms. Over a two-week period, CO2 levels were recorded in which the two classrooms were typically occupied. CO2 levels were considered the most important indicator as they are primarily the result of respiration and can logically be related to the airborne spread of disease. Figure 2 illustrates a typical daily plot of the CO2 concentrations in the two classrooms. Note that the levels in the classroom served by the unit ventilator increase rapidly as the classroom becomes occupied and then remain relatively constant throughout the day. There were slight peaks and valleys that results from periods when the classroom was unoccupied (recess, lunch, etc.), but these normally lagged the change in occupancy by half an hour or more. The overall average classroom CO2 level was approximately 1100 PPM.

In contrast, the average CO2 levels in the classroom served by the displacement (QLCI) system averaged 400 PPM, or 65% lower than those found in the original classroom. In addition, unoccupied periods were clearly evidenced by a sharp (and immediate) drop in CO2 levels. This should be expected as displacement systems remove airborne contaminants at the source, as opposed to simply diluting their concentration within the space. Therefore the odds of an occupant contracting a disease by airborne means were reduced by a similar 65% as well.

Summary

Since the mock-up, the school district has retrofitted eleven schools with the QLCI system and has a number of other retrofits scheduled for 2007 and beyond. Citing the results of the District, several other districts in Minnesota have also used the QLCI system in both retrofit and new construction applications.

Purdue University Substantiates QLCI Operation of Year-Round Displacement Ventilation

Questions continue to arise surrounding the correct value to apply for ventilation effectiveness, Ez, when determining code required minimum outside air per Table 6-4, ASHRAE 62.1-2019. In Table 6-4, ASHRAE outlined default values based upon distinct ventilation type and finite operational characteristics.

ASHRAE recognized the default values in Table 6-4 could not capture the myriad of ventilation and equipment designs, not to mention the enhanced control strategies, applied in industry practice.

Normative Appendix C defines the procedure for determining zone distribution effectiveness through the following measures: (1) CFD modeling coupled with supporting lab validated testing and (2) operational performance must be measured in BOTH cooling and heating modes.

In Table 6-4, for Stratified Air Distribution Systems, (Displacement Ventilation) the Ez default values were only defined for cooling mode operation. Now with the defined procedures per Normative Appendix C, the ability to establish Ez values for Displacement Ventilation during heating modes can now be applied.

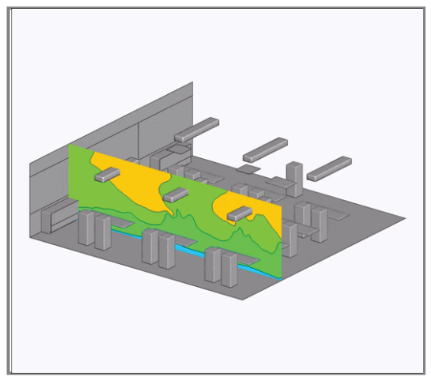

Ventilation in HEATING mode.

Ventilation in COOLING mode.

Displacement Out Performs Mixed Air Ventilation for Contaminant Removal

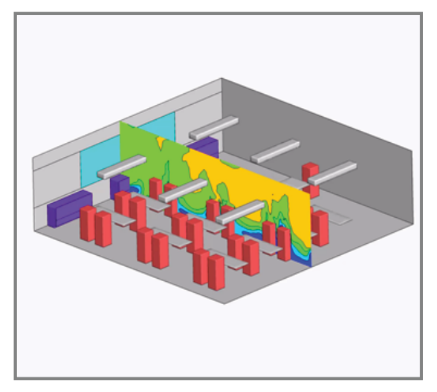

Designers should investigate a method called vertical displacement ventilation or thermal displacement ventilation. This approach successfully uses natural convection forces to reduce fan energy and carefully lift air contaminants up and away from the breathing zone

Schools receive better IAQ, improved thermal comfort, improved acoustics for learning, and decreased maintenance with no moving parts.

Not All Displacement Ventilation is Created Equal

Go with a tested, validated and proven leader:

- Hundreds of school buildings with QLCI installed over decades.

- Many school districts have installed QLCI equipment repeatedly based on delivered performance.

- Fully customizable equipment and accessories.

- Only DIV manufacturers to have 3rd party independent data per ASHRAE 62.1-2019 Normative Appendix C.

- Validated stratified displacement operation in BOTH cooling and heating modes.

About Carson Solutions

Carson Solutions designs and manufactures HVAC equipment designed for occupied environments. We focus on innovative products that exceed industry standards to assist in providing the best environments in which we work and live. At Carson Solutions, we are devoted to improving the well-being of people and the occupied environments in which we work and live by producing innovative sustainable solutions that solve our customer’s needs and challenges.